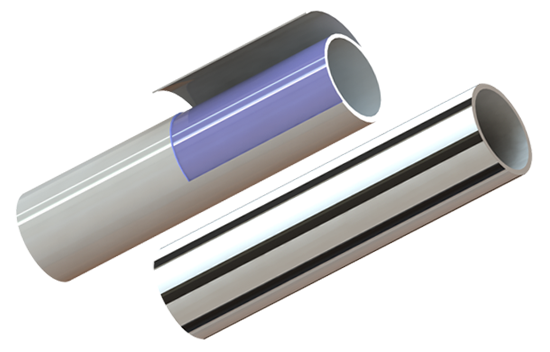

ESD and LPP Tube

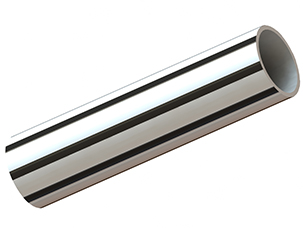

- ESD Tubes can prevent potential problems of electrical discharge that occurs in the dispensing operation of bulk solvents in semiconductor manufacturing plants.

- Prevents the possibility of ignition of sparks, combustible gases and organic solvents caused by static electricity.

- Prevents the possibility of ignition due to fluid friction caused by transport of organic solvents

- Prevents destruction of insulator’s physical properties due to high voltage current, temperature, humidity, etc.

- ESD Tube can be produced in standard dimensions from 1/4″ to 2″ size

Spec Sheets and Ordering Information

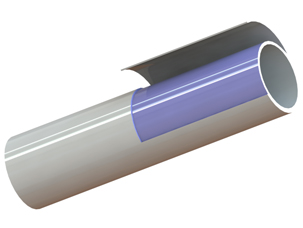

LPP Tube

ESD Tube

LPP Tube

· Operating Specification

| Operating Temperature | Maximum Operating Pressure | |

| Tube | 0~90℃ | 9㎏/㎠(0.9Mpa) |

| 90~120℃ | 7㎏/㎠(0.7Mpa) | |

| Over 150℃ | Below 5㎏/㎠(0.5Mpa) | |

· Material Construction

| Inner Layer | Outer Layer |

| 231SH | CPT LP1030 |

| 70% of the total wall thickness | 30% of the total wall thickness |

· Product Specifications – Dimension Table

| Tube Size | 1/4″ | 3/8″ | 1/2″ | 3/4″ | 1″ | 1-1/4″ | 1-1/2″ | 1-1/2″ | 2″ | |

| Out Dia | mm | 6.35 | 9.53 | 12.70 | 19.05 | 25.40 | 31.80 | 38.10 | 40.00 | 50.80 |

| inch | 0.250″ | 0.375″ | 0.500″ | 0.750″ | 1.000″ | 1.251″ | 1.500″ | 1.574″ | 2.000″ | |

| Out Dia Tolerance | ㎜ +/- | 0.102 | 0.102 | 0.127 | 0.127 | 0.127 | 0.203 | 0.203 | 0.203 | 0.254 |

| Thickness | mm | 1.19 | 1.57 | 1.57 | 1.57 | 1.57 | 1.90 | 2.18 | 2.18 | 2.40 |

| inch | 0.048″ | 0.062″ | 0.062″ | 0.062″ | 0.062″ | 0.075″ | 0.086″ | 0.086″ | 0.094″ | |

| Thickness Tolerance | ㎜ +/- | 0.102 | 0.127 | 0.127 | 0.127 | 0.127 | 0.127 | 0.127 | 0.127 | 0.127 |

| In Dia | mm | 3.97 | 6.39 | 9.56 | 15.91 | 22.26 | 28.00 | 33.74 | 35.64 | 46.00 |

| inch | 0.156″ | 0.251″ | 0.376″ | 0.626″ | 0.876″ | 1.102″ | 1.328″ | 1.403″ | 1.811″ | |

| Application Length(M) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |||

| 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |||

| 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |||

ESD Tube

· Operating Specification

| Operating Temperature | Maximum Operating Pressure | |

| Tube | 0~90℃ | 9㎏/㎠(0.9Mpa) |

| 90~120℃ | 7㎏/㎠(0.7Mpa) | |

| Over 150℃ | Below 5㎏/㎠(0.5Mpa) | |

· Material Construction

| Strap | Wetted Area |

| 230ASL | 231SH |

· Product Specifications – Dimension Table

| Tube Size | 1/4″ | 3/8″ | 1/2″ | 3/4″ | 1″ | 1-1/4″ | 1-1/2″ | 1-1/2″ | 2″ | |

| Out Dia | mm | 6.35 | 9.53 | 12.70 | 19.05 | 25.40 | 31.80 | 38.10 | 40.00 | 50.80 |

| inch | 0.250″ | 0.375″ | 0.500″ | 0.750″ | 1.000″ | 1.251″ | 1.500″ | 1.574″ | 2.000″ | |

| Out Dia Tolerance | ㎜ +/- | 0.102 | 0.102 | 0.127 | 0.127 | 0.127 | 0.203 | 0.203 | 0.203 | 0.254 |

| Thickness | mm | 1.19 | 1.57 | 1.57 | 1.57 | 1.57 | 1.90 | 2.18 | 2.18 | 2.40 |

| inch | 0.048″ | 0.062″ | 0.062″ | 0.062″ | 0.062″ | 0.075″ | 0.086″ | 0.086″ | 0.094″ | |

| Thickness Tolerance | ㎜ +/- | 0.102 | 0.127 | 0.127 | 0.127 | 0.127 | 0.127 | 0.127 | 0.127 | 0.127 |

| In Dia | mm | 3.97 | 6.39 | 9.56 | 15.91 | 22.26 | 28.00 | 33.74 | 35.64 | 46.00 |

| inch | 0.156″ | 0.251″ | 0.376″ | 0.626″ | 0.876″ | 1.102″ | 1.328″ | 1.403″ | 1.811″ | |

| Application Length(M) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |||

| 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |||

| 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |||

For more information on our full line of products, please contact a sales representative.